-

CONTACT USMORE |

|

National unified service hotline: 400-8745-888 Waterproof material: Mr. Luo Bin 13707219720

Dong Jian Dong 13969021288 Factory Address: No. 9, Industrial Park, Hougang Town, Shayang County, Jingmen City, Hubei Province |

|

Industry News |

- How to choose waterproof materials in different regions of the north and south

- Publisher:中聘金禹Release time:2023-01-10 17:11:13Views:0次

The impact of climate environment on people's lives and residences cannot be underestimated. In addition to affecting people's daily travel, living habits, etc., it also has many impacts on the waterproof materials and construction techniques selected during construction. my country has a vast territory, and the temperature difference between the north and the south is huge. In some areas of the south, the temperature in summer reaches over 40 degrees, which lasts for several days. The waterproof layer of the roof is exposed to the sun for a long time, and the waterproof performance declines rapidly. The selected materials should be waterproof materials with strong UV resistance and high softening point. Now, let's talk about how to choose waterproof materials in different regions of the south and the north!

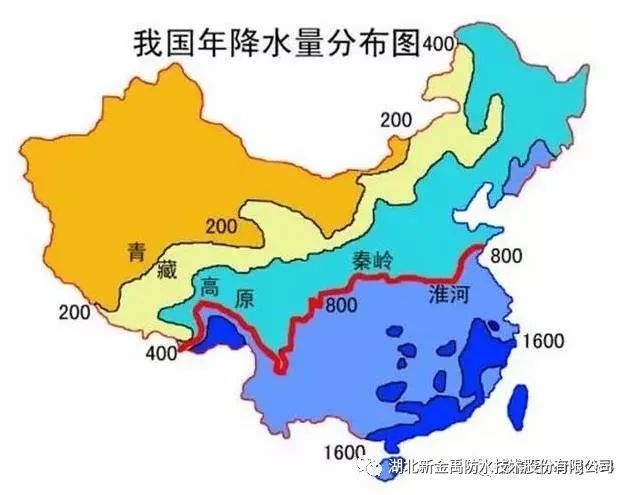

Rainy in the south, snowy in the north, and dry in the west

There are about 15 provinces, municipalities and autonomous regions with an annual rainfall of more than 1,000 mm. On rainy days, the roof is always wet, and the drainage is not smooth, and there may even be water accumulation, which will not dry up for several months, soaking the waterproof layer. Paints with poor water resistance are prone to re-emulsification or hydration reduction reactions; adhesives that are not resistant to blisters seriously reduce the bonding strength, causing the polymer membranes in the bonded joints to crack, especially the gutters for internal drainage, which will leak due to long-term soaking in water. For this reason, waterproof materials with higher water resistance should be selected, such as modified asphalt membranes with glass fiber or polyester tires, or polymer membranes bonded with water-resistant adhesives. As for the arid and rainless northwest region, evaporation is much greater than rainfall, and often no water is seen on the eaves after rain. These regions obviously have lower requirements for waterproofing. A secondary building with a defense layer can also meet the waterproofing requirements. If a good protective layer is built, there is no problem in reaching the durability.

In cold and snowy areas, some waterproof materials cannot withstand the cycle of low temperature expansion and contraction, and will age and break in a short time. Four or five months a year are covered with white snow, and the snow water soaks the waterproof layer for a long time. At the same time, the snow melts and freezes. Adhesives with poor frost resistance and poor water resistance will become vulnerable in such a harsh world. In addition to the influence of the region on the selection of materials, the seasonal selection of waterproof construction cannot be ignored. In the cold winter, water-soluble coatings cannot be used, and the adhesive will reduce its bonding performance at 5°C, and it cannot be constructed at sub-zero temperatures. The design was in summer, and the construction was in the coldest days of winter. The adhesive froze and lost its adhesion when it met the concrete. The self-adhesive waterproofing membrane could not stick to the seams, resulting in construction failure, delays in construction period, and waste of materials and labor. In the Northeast, some projects used waterproof materials with low low-temperature indicators in the summer, but in the severe winter, these completed waterproof layers could not withstand the ravages of frost expansion and contraction, and were prematurely abandoned. When designing, attention should be paid to understanding the adaptability of the selected materials. Key points for quality control of waterproof engineering construction

01 Quality control of roof base and environmental conditions To ensure the quality of roof waterproofing construction, it is necessary to start from the various structural layers of the roof. Regardless of the type of waterproofing material, the surface of the base layer must be clean, dry, and the construction temperature must be suitable. The concrete strength meets the design requirements, the joints are densely filled, the air barrier layer is evenly coated, and there is no white exposed bottom; the insulation layer is laid according to the design requirements, and the thickness and slope are accurately controlled to ensure smooth drainage; before the construction of the leveling layer, an elevation reference point should be made, and the surface of the base layer should be compacted, flat, and polished twice, and fully maintained, without looseness or sand.

02 Construction process quality monitoring For the construction of waterproof base and waterproof layer at all levels, formulate the acceptance system before each waterproof construction, strictly organize the acceptance according to the acceptance procedure of concealed works, and do on-site supervision in key processes and key parts. Strictly check whether all technical data meet the standard requirements, attach importance to the collection of construction technical data, and do a good job of construction logs, on-site supervision records and concealed project acceptance records. If the technical data is incomplete and the construction quality does not meet the standard requirements, the next process shall not be carried out. At the same time, the method of leading by example is promoted, that is, after the model is approved by Party A, supervision, owner, and design, the scope of construction will be expanded to further improve the construction organization design plan and achieve effective control.

03 Strengthen the quality control of detailed structures Joints, corners, and nodes such as building deformation joints, post-casting strips, through-wall pipes, parapets, and rainwater inlets are important parts that are prone to roof leakage. The construction quality of these key points and node parts is the focus of supervision work. It is necessary to adopt a combination of active control, dynamic management and on-site supervision. Before pouring concrete, the water stop strips at the deformation joints, the templates at the post-casting strips, and the fixing of through-wall pipes must be carefully inspected and accepted. When constructing roof waterproofing, it is required to first do a good job of processing the nodes, additional layers, and the more concentrated drainage areas of the roof, and then construct from the lowest elevation of the roof upwards. The overlap, pasting sequence, overlap length, width, parapet wall flashing height, and edge pressing treatment are all inspected and accepted to ensure the waterproof quality of the detailed structure. - Hot Keywords:

|

|